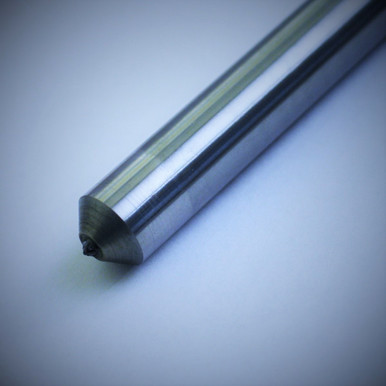

0.50 carat 9.53 x 125mm (3/8" x 5") shank.

| Results of Neglect - you may recognise these signs. |

- Chatter or gouge marks - Diamond broken or chipped.- Diamond lines on work - Increased diamond wear or broken diamond.

- Chatter marks on work - Diamond is dull and is crushing rather than dressing the wheel.

- Reduced diamond life due to burning - poor flow of coolant on diamond whilst dressing.

|

| Tips - Maintaining your Diamond Dressing Tools |

- A dull diamond tends to crush the grains into the bond of abrasive wheels and crack them without giving a clean break.

- Grains of wheels that have been crushed in this manner will give the effect of wheel loading - cracked grains will also come out whilst grinding and produce scratch marks in work.

- Some precautions when setting up a diamond tool

- Be sure diamond holder is securely held with minimum overhang.

- Be sure diamond is not cracked, burned or flatted.

- Be sure, whilst dressing, the diamond is not subjected to excessive shocks or bumps.

- For best grinding finishes be sure diamond cutting angle is not too sharp.

- Be sure, whilst dressing, the contact point of the diamond receives plenty of coolant.

- Whilst dressing, diamond cuts should not exceed 0.001" per pass.

|

Library picture used for illustration purposes.

Loading... Please wait...

Loading... Please wait...